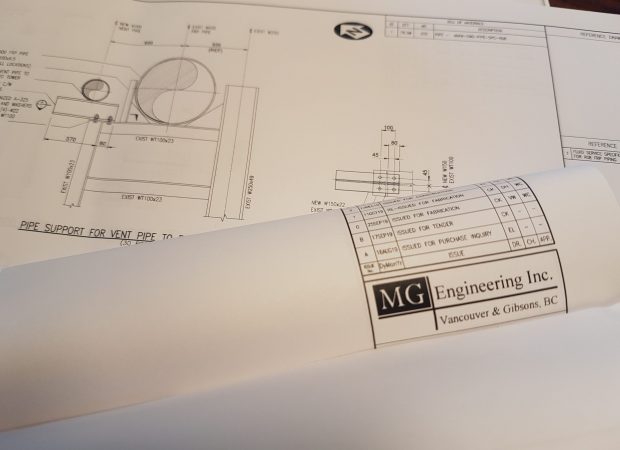

MG Engineering provides engineering and design services for a number of disciplines. The engineering services include calculations according to industry standards and codes, calculations for process design, and field engineering services. MG has extensive experience in brownfield projects and understands the challenges of integrating a project into an operating plant.

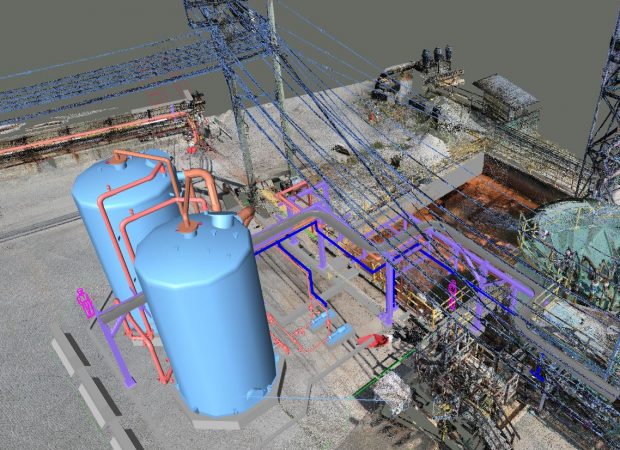

MG provides design in CAD format including 3D modeling. Their designers are experienced in mechanical and piping for heavy industries, along with civil and structural, and electrical and instrumentation.

MG engineers and designers work closely together, and work well on multi-disciplinary projects.

PROCESS ENGINEERING

MG Process Engineers and Specialists work with all levels of plant personnel to provide engineering, studies and technical support.

Engineering Services:

- Process design

- Heat and mass balances

- Equipment and instrumentation sizing and specifications

- Process and control drawings (P&C’s)/Process and instrumentation diagrams (P&ID’s)

- Process interlock and logic functional descriptions

- Participation in HAZOP studies

Operational Services:

- Field review of existing operations

- Process troubleshooting

- Identification of process bottlenecks

- Production increase studies

- Commissioning and start-up

- Development of operator training programs and operation manuals

PROJECT EXAMPLES

CIVIL/STRUCTURAL ENGINEERING AND DESIGN

MG Civil/Structural Engineers are Professional Engineers registered in Western Canada and the Western United States. All engineering work is performed in accordance with applicable industry standards, typically including the National Building Code.

Specific support capabilities of MG Civil/Structural Engineers and Designers include:

Project Services:

- Cost estimating

- Technical specifications and scope of work documents for contract tendering

- Procurement assistance of pre-engineered buildings and structural steel

- Compliance reviews of structural steel fabrication drawings

- Civil/Structural design standards

- Drawings (including layouts, plans and sections, supports and hangers, foundations, fabrications, structural steel, 3D, etc)

Structures and Roadways:

- Steel, concrete, and timber structures

- Industrial buildings

- Piling and foundations

- Retaining walls

- Upgrades/modifications to existing structures and rooftops

- Lifelines and fall arrest anchors

- Access roadways, ramps, and drainage systems

Equipment and Piping Supports:

- Piling and foundations

- Equipment support pads

- Lifting beams

- Pipeline supports and thrust blocks

- Pipe bridges and conveyor structures

- Vibratory equipment supports and dynamic analysis

- Access platforms and stairways

Site and Inspection Services:

- Contract administration

- Construction progress monitoring

- Construction site inspections

- Building inspections

- Failure analysis

- Inspection and certification of monorails and load lifting points

- Inspection and certification of lifelines and fall arrest anchor points

PROJECT EXAMPLES

MECHANICAL/PIPING ENGINEERING AND DESIGN

MG’s Mechanical Engineers are Professional Engineers registered in Western Canada and the Western United States. All engineering work is performed in accordance with applicable industry standards, including: ASME Section VIII, B31.1, B31.3, API 650, API 653, Worksafe BC, and OSHA.

Specific support capabilities of MG Mechanical Engineers and Designers include:

Project Services:

- Equipment bid package reviews and comparisons

- Scope of work and specifications for contract tender documents

- Attendance of pre-bid meetings with contractors to review contract scope

- Development of design standards

Mechanical Equipment:

- Analysis of existing pumping systems for energy efficiency

- Mechanical equipment technical specifications (ex. sizing and selection of conveyors, heat exchangers, pumps, etc.)

- General Arrangements and mechanical layouts

- Over pressure protection device specifications for unfired tanks and pipelines

Tanks:

- Tank sizing

- Tank data sheets

- Pressure rating analysis (with accordance to ASME Section VIII)

- Tank modifications (ex. convert closed tank into open-top tank, nozzle specifications for tank service changes, etc) to meet API 650/API653 Standards

- Specifications for secondary containment

- Coordination of repairs based on inspection reports (scope of work, cost estimates, schedules, construction management)

Piping and Pipelines:

- Piping design for slurry, water, steam, compressed air, etc. through carbon steel, stainless steel, FRP, and other types of piping material.

- Piping drawings (including isometrics with bill of materials, plans & sections, pipe supports, tie-ins, and 3D drawings)

- Development of project specific piping design standards and flushing and testing procedures

- Lock out procedures to meet existing codes and regulations (ex. ASME B31.1/B31.3 & Worksafe BC)

- Pressurized piping registration

- Pipe stress analysis

- Design of long-distance underground pipelines

Site and Inspection Services:

- Supervision of flushing and testing

- Preparation and coordination of repair programs

PROJECT EXAMPLES

ELECTRICAL/INSTRUMENTATION ENGINEERING AND DESIGN

MG Electrical Engineers and Technologists work with all levels of plant personnel to provide operations, engineering, quality control and technical support. Specific support capabilities of MG Electrical Engineers and Technologists include:

Electrical Design:

- Electrical systems design and specification

- Power system design

- Electrical system studies including load flow, short circuit, protection coordination and harmonics analysis

- Electrical safety analysis and remedial design (i.e. arc flash protection)

- Development of electrical system preventative maintenance programs

- Electrical system maintenance coordination (i.e. bus inspections, protection relay calibrations, etc.)

- PLC design and specifications

- Development of preventive maintenance systems

Instrumentation Design:

- Instrumentation and DCS design and specifications

- Control system design and troubleshooting

- Commissioning and start-up of new control systems

- Evaluation of spare parts requirements

- Development of process control strategies

- Communications system design

EXAMPLE PROJECTS

HYDRAULICS ENGINEERING SPECIALIST

MG’s Hydraulics Engineering Specialist holds a BASc in mechanical engineering, a PhD in mining engineering, and is an Adjunct Professor (rheology and slurry transport) at UBC. He has expertise with the transportation of slurries, pastes, and non-Newtonian fluids. Specific support capabilities include:

Engineering Services:

- Process design

- Rheological testing interpretation

- Mass balances, process flow diagrams and P&C’s/P&ID’s

- Friction loss and pipeline pressure profile analysis

- Operating range analysis (e.g. deposition velocity)

- Equipment, pipe, and fittings sizing and specifications

- Process control narratives (interlock and logic functional descriptions)

Fluid Types Analyzed:

- Non-Newtonian fluids (backfill paste, sludge)

- Two phase suspensions (mineral slurry, wood pulp)

- Newtonian liquids (water, caustic and acid solutions, oil)

- Gases and vapours (air, steam, oxygen, NCG)

Fluid Handling Systems and Equipment:

- Tanks, agitators, pump chests, and drop boxes

- Pumps (centrifugal and positive displacement)

- Pipe and fittings

- Hydrocyclones, choke stations, spray bars

- Open channel launders