Wrap Line

Wrap Line

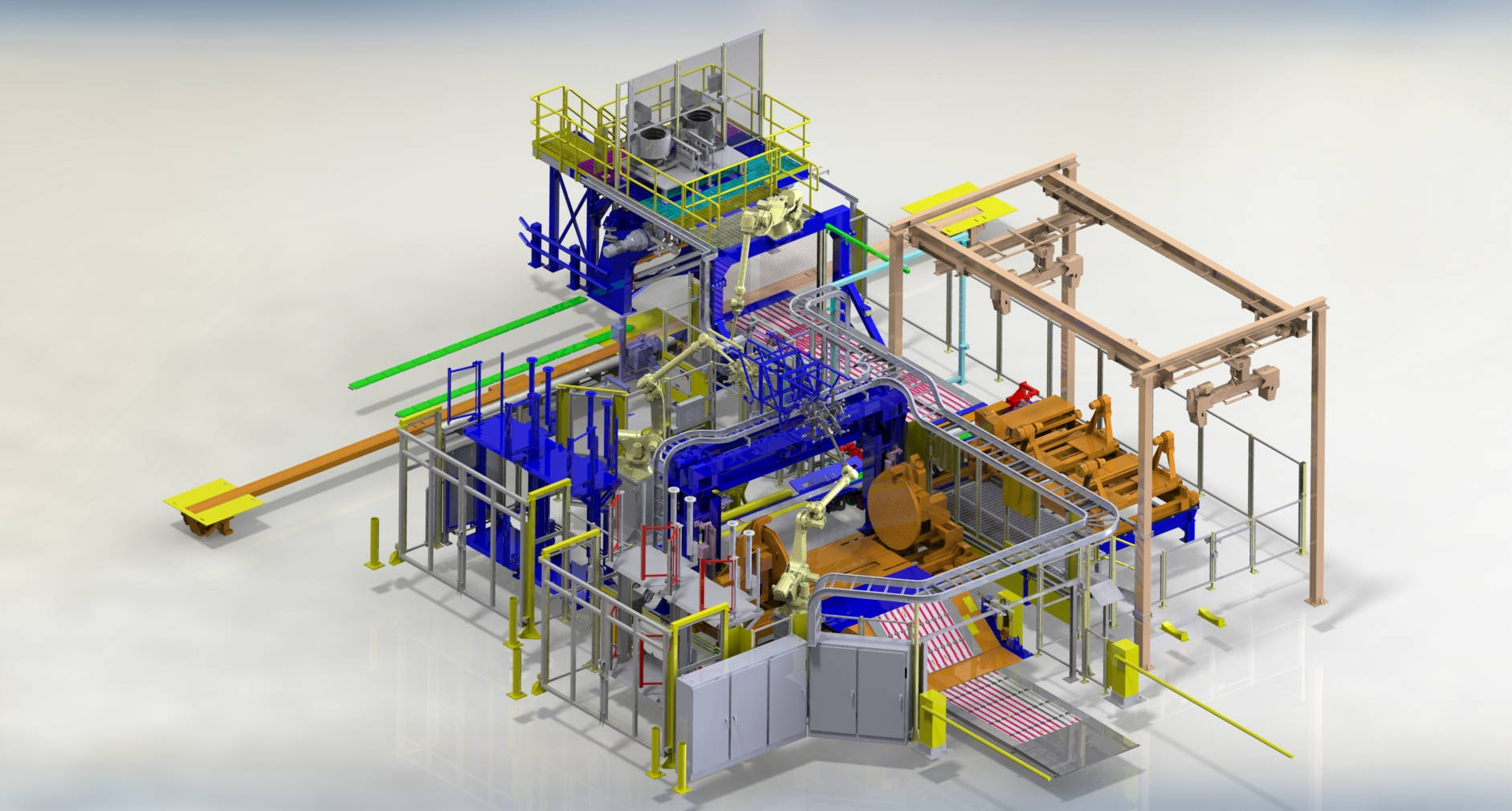

MG worked for the Canfor PG Pulp Mill to facilitate the selection, purchase and installation of a new, fully automated, roll wrapping line for their No.1 Paper Machine. MG provided cost estimating and procurement services during the vendor selection process, and supported the project with mechanical and structural engineering, as well as Vendor drawing control services, throughout the installation.

The wrap line equipment was provided by Advanced Dynamics as a set of pre-fabricated, factory tested modules.

The new wrap line was installed primarily in order to improve operator safety, and also to bring it up to modern standards. The new system is robot operated and fully enclosed by a perimeter safety fence – no live operator involvement required.

Installation of the new line was achieved over several months while the paper machine and its existing wrap line continued to operate normally. Once commissioned, the new line was brought into service during a one day turnaround.

The existing mill floor and its supporting steel structure required considerable strengthening in order to support the increased loads of the new equipment. This work was done without interrupting mill production.

- Location: Prince George, BC - Canfor

- Category: Civil/Structural Estimating Mechanical/Piping Pulp and Paper