Pipeline Replacement – Sodium Sesquisulfate

Pipeline Replacement – Sodium Sesquisulfate

MG Engineering (MG) worked with Canfor personnel in Prince George, BC to provide cost estimates and mechanical engineering for the replacement of their 30-year-old FRP Sodium Sesquisulfate pipeline which runs between Canfor’s PG Pulp and Intercon pulp mills.

The project was executed in phases using Canfor’s formal Project Procedure Instructions.

During the first ‘Concept Development’ phase the process requirements were examined, several potential construction materials & methods were reviewed and an AACE class 5 capital cost estimate was produced.

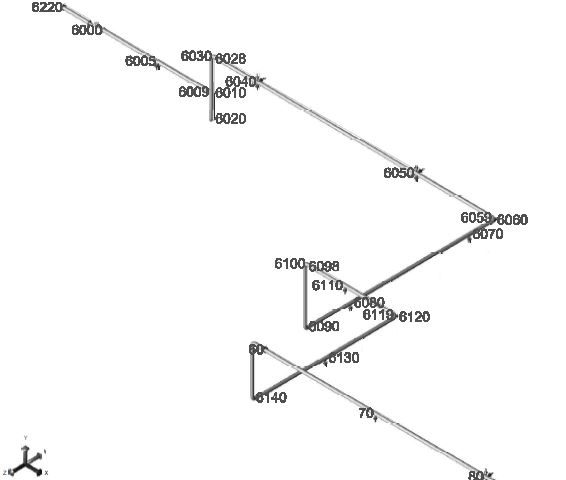

The second ‘Definition Study’ phase involved a preliminary layout compete with flexibility analysis using Caesar II software, and included an AACE class 3 estimate and an AACE class 2 project schedule.

This was followed by the final ‘Detail Design’ phase in which the pipe and pipe support designs were finalized, a Scope of Work document produced and the complete package released for Construction.

Pipeline flexibility was a primary concern during the design because the pipeline had design temperatures ranging from -40 to + 40 deg C, had a long length (runs from one mill to the other), and was constructed with FRP which has a relatively high thermal expansion coefficient. Multiple expansion loops were required to satisfy these requirements.

The pipeline was constructed using factory-made ‘Centricast’ FRP pipe. Centricast uses bell and spigot type connections, so installation was relatively quick and easy – with no field wraps required. The pipe was also factory insulated which also helped speed-up the installation process.

- Location: Prince George, BC - Canfor

- Category: Chemical Estimating Mechanical/Piping Project Management Pulp and Paper