Membrane Caustic Modernization

Membrane Caustic Modernization

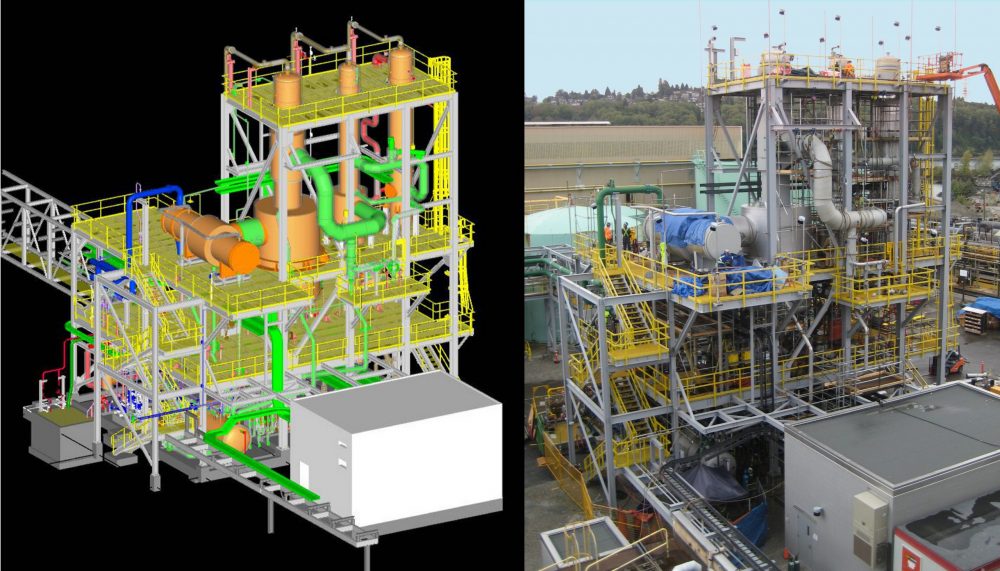

The Chemtrade facility in North Vancouver, BC replaced its caustic evaporation plant with a new three-stage evaporation facility. Chemtrade engaged MG Engineering to provide engineering, procurement assistance, and construction management. The scope of design included the evaporation plant structure and foundations (utilizing a 3D model), utility bridges, process/service piping and piping tie-ins. The new plant will reduce steam consumption, and lower operating and maintenance costs.

MG prepared both the pre-feasibility and appropriation capital cost estimates for the project in 2012-2013. Detailed engineering was awarded in 2014 and included project management, detailed design, technical specifications for price inquiries, contract tender documents, bid comparisons, permitting, project scheduling and field inspections. Close coordination with other consultants and vendors was required to ensure there were no interferences between the equipment, structure, piping, and electrical and instrumentation services.

Construction management services were provided by MG and included project planning, cost monitoring, quality management, material receiving, contract administration, site safety, and monitoring the construction schedule.

Construction began in January of 2015 with start-up in October 2015. The project was on-time and under budget.

- Location: North Vancouver, BC

- Category: Chemical Civil/Structural Estimating Mechanical/Piping Project Management Site Assistance