Coal Conveyor Modifications

Coal Conveyor Modifications

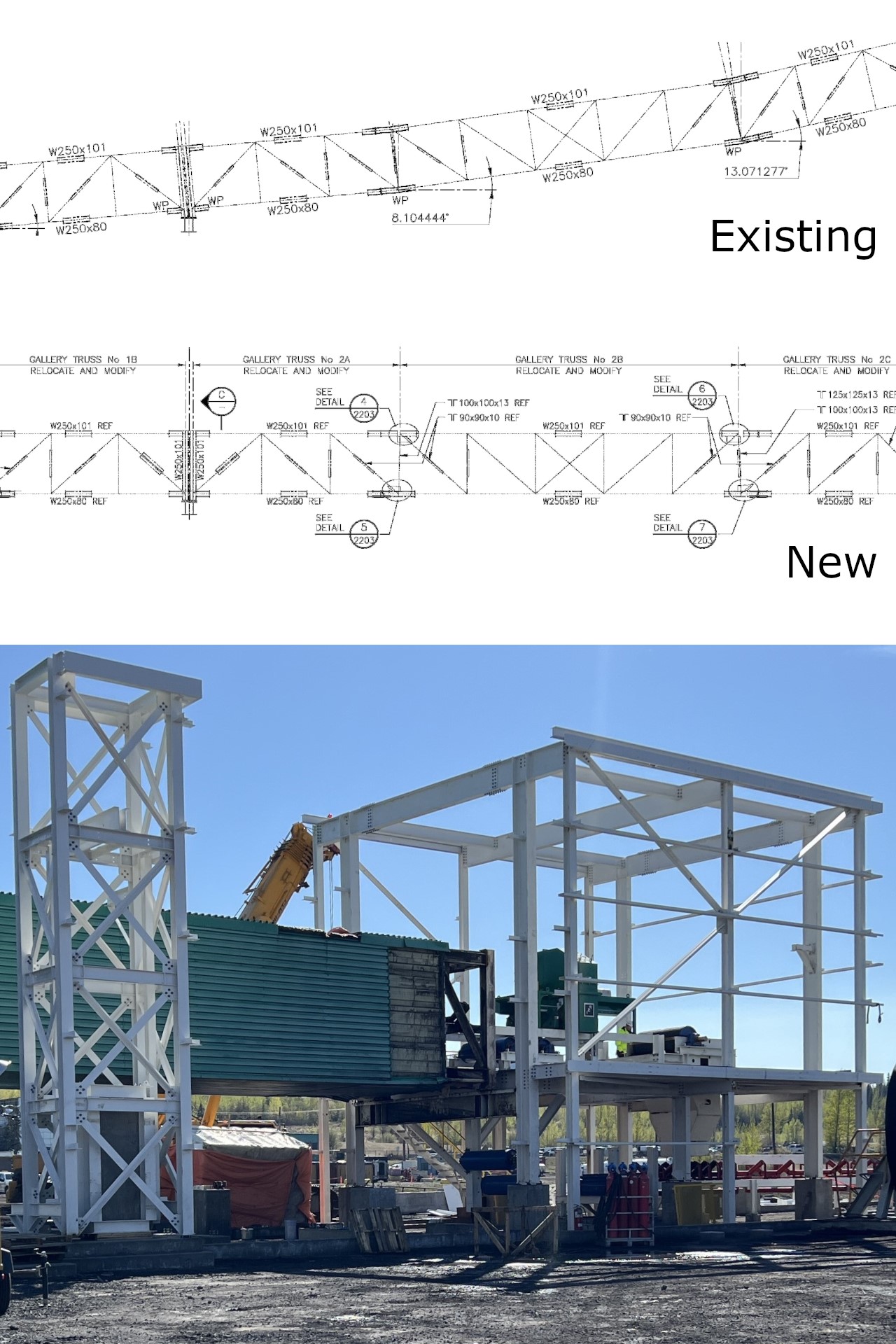

MG Engineering (MG) engaged in the modification of a belt conveyor for a client in Northern BC. The conveyor and trusses needed to be modified and re-erected in a horizontal profile (instead of feeding a taller building, the conveyor will be feeding into a significantly shorter transfer tower). The structural engineering team prepared sketches and drawings for truss modifications, which included the design and detailing of connections for the top and bottom chord members of the truss sections.

The existing bents were shortened and reused to support the new conveyor configuration. Since no modifications were anticipated for the bent foundations, these foundations needed to be checked against the overturning from the seismic and wind loads as per the latest building code. MG designed the new transfer tower at the head end of the conveyor. This transfer tower will be enclosed with roofing and cladding.

Conveyor take-up options were evaluated. A dual gravity take-up option would have limited space for maintenance activities. Considering the functional requirements and needs of the client, MG discussed a horizontal take-up configuration. This chosen option was designed with a sled and track system enclosed under the conveyor gallery and a separate take-up tower erected adjacent to the conveyor gallery.

- Date: 14th of February, 2026

- Category: Aggregates, Ports and Terminals Civil/Structural